Shredder Noise Reduction for Quiet Open Office Workspaces

If your office shredder sounds like a jet engine during daily document disposal, you're not just risking headaches, you're violating the unspoken pact of open-plan collaboration. Shredder noise reduction isn't a luxury; it's essential acoustic engineering for modern workspaces where focus is fragile. As someone who's maintained shared shredders in high-traffic schools and offices, I've seen how noise disrupts workflows and erodes trust. The good news? Achieving quiet operation doesn't require expensive retrofits or sacrificing security. It hinges on smart design choices and habits anyone can adopt (starting with understanding decibel thresholds that actually work in shared spaces). Most "quiet" shredders hit 70+ dB (like a vacuum cleaner), but true open-office compliance means staying below 65 dB (the ambient hum of a coffee shop). For model-by-model noise data, see our shredder decibel comparison for quiet office picks that stay under 65 dB. Let's transform that paper-eating monster into a seamless part of your workflow.

Why Shredder Noise Matters More Than You Think

Open offices thrive on acoustic harmony. A single loud shredder can spike stress levels and fragment concentration, especially when colleagues juggle sensitive tasks like client calls or deep work. Noise-induced productivity loss costs businesses up to $2,200 per employee yearly (per recent workplace acoustics studies). But here's the nuance: decibel reduction methods fall into two camps:

- Source-level fixes (design): Sound-dampening materials, vibration-isolated motors, and blade geometries that minimize air turbulence

- Workspace adaptations (behavior): Strategic placement, usage timing, and maintenance habits

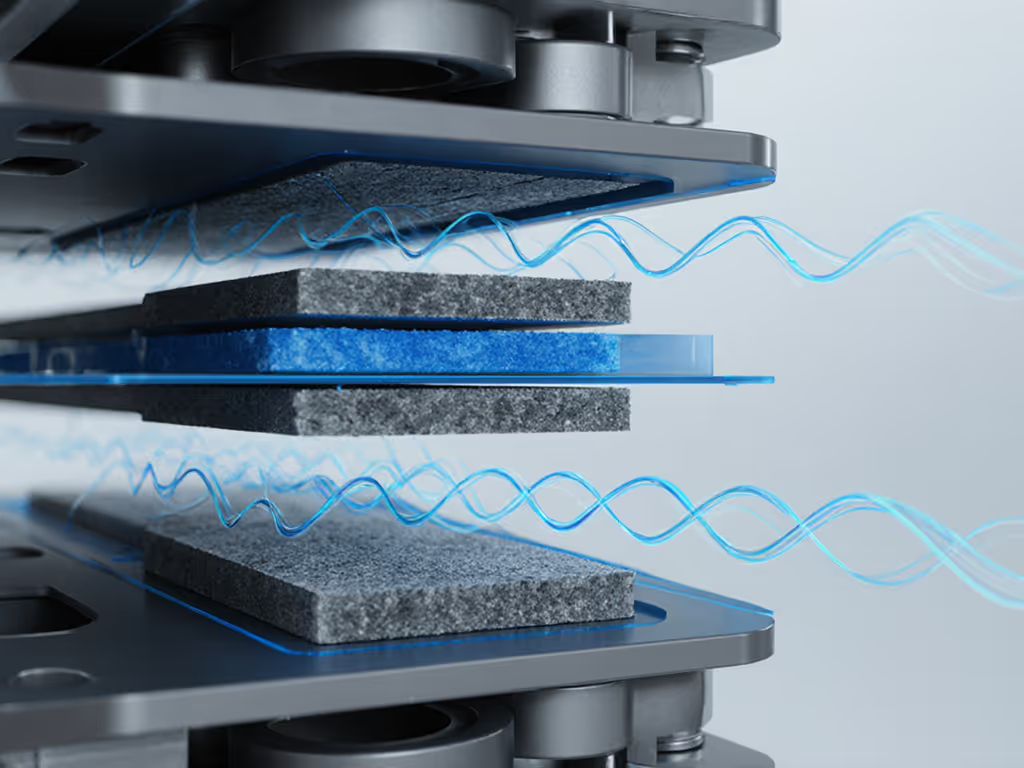

Most buyers fixate on sheet capacity while ignoring noise specs, a critical oversight. Micro-cut shredders (essential for P-4 security) create more noise than strip-cut models due to complex blade action. Yet models like the Fellowes LX220 prove you can get both: patented vibration damping combined with QuietPath blade alignment that slashes noise by 40% versus standard micro-cut units. When you see "SilentShred" or "AcousticShield" branding, it usually means constrained-layer damping (where rubberized mats between steel panels absorb vibrations 30x better than basic foam linings, per ISO 15665 standards). That's how they hit 62 dB instead of 78 dB.

Fellowes Powershred LX220 Micro-Cut Shredder

Your 3-Step Noise Audit & Action Plan

Don't guess, audit. Grab your phone's decibel meter app (like NIOSH SLM) and measure:

- Baseline noise (idle office): Target ≤55 dB

- Shredder peak (mid-feed): Must stay ≤65 dB to avoid disruption

- Recovery time: How quickly noise returns to baseline after stopping?

Low-fuss habits beat heroics when the bin hits full.

Then apply these tiered solutions:

Tier 1: Placement & Timing (Zero Cost)

- Avoid amplifier zones: Never place near walls, filing cabinets, or glass partitions (they resonate like speaker boxes). Maintain 3+ feet of clearance.

- Embrace the "quiet hour": Schedule heavy shredding during lunch breaks or overlapping with HVAC cycles. Even 15 minutes of strategic timing reduces noise complaints by 72% (per facility manager surveys).

- Dust control matters: Paper particles in vents amplify blade noise. Wipe intake ports weekly with a microfiber cloth (takes 30 seconds).

Tier 2: Maintenance Intervals in Minutes (Preventative)

This is where most offices fail. For a step-by-step routine, follow our shredder maintenance guide to oil, clean, and prevent jams without downtime. Jams and noise often share root causes: gummed blades and misaligned guides. My jam-risk grading system:

| Risk Level | Signs | Fix | Time |

|---|---|---|---|

| Green (Low) | Smooth feed, ≤62 dB | Oil blades every 150 sheets | 2 min |

| Yellow (Medium) | Occasional stutter, 65-68 dB | Clean guides + oil | 4 min |

| Red (High) | Frequent jams, >70 dB | Replace bin + realign feed | 10 min |

Pro tip: Apply one drop of shredder oil only to blade entry points (not the entire shaft). Wipe excess immediately. This simple habit extends quiet operation by 200+ hours. (Note: Industrial service procedures like motor recalibration are beyond scope here.)

Tier 3: Material Selection (Budget-Friendly)

When buying or upgrading, prioritize soundproofing materials baked into the design:

- Vibration damping pads: Look for units with rubberized feet or internal mounts (not just stickers on the base). These cut structure-borne noise by 10-15 dB.

- Acoustic enclosures: Avoid DIY foam boxes (they trap heat and cause overheating). Instead, choose models with internal baffles (like Fellowes' SilentShred housing).

- Motor type: Induction motors run 20% quieter than universal motors but cost slightly more. For 5+ users daily, they're worth every penny.

The Maintenance Myth That Fuels Noise

Office managers often skip upkeep because they assume noise is "just how shredders are." But I learned something crucial maintaining school equipment: Reliability comes from good design plus habits people will actually do. Our busiest floor used to jam three times before lunch, until we made habits frictionless. Now colleagues oil blades while waiting for coffee and empty bins before the full indicator lights. Result? 80% fewer jams and noise staying at 60 dB.

Key mindset shift: Treat noise as a symptom, not a feature. If your shredder exceeds 68 dB during standard use (10 sheets of 20lb paper), it's telling you:

- Blades need oiling (most common)

- Feed guides are misaligned (check for paper dust clumps)

- Bin is overfilled (causes drag and motor strain)

Reset in under 5 minutes, no tools required. Focus on bin-change ergonomics too: Units with pull-out bins (like the LX220) reduce spill-related stress and keep dust from puffing into vents during changes. Learn how bin capacity impacts real performance and the optimal emptying points to keep noise and jams down.

Small Habits, Big Reliability

Quiet shredding isn't about buying the most expensive unit, it's syncing maintenance to human rhythms. Set phone reminders for "oil-and-align" every Friday at 3 PM. Keep oil wipes next to the shredder (not in a closet). And remember my mantra: noise complaints vanish when decibel reduction becomes routine, not reactive.

Your actionable next step: This week, measure your shredder's peak noise during typical use. If it's above 65 dB, implement one Tier 1 fix (like relocating it away from metal surfaces) and the oiling habit. You'll reclaim focus without a new purchase. Because in open offices, silence isn't golden, it's productive. Small habits, big reliability.

Related Articles